Tokyu's technology is shining in the field of car air conditioning parts.

A compressor located at the heart of a car air conditioner is an essential part for a peaceful, safe and comfortable car life. We are involved with manufacturing the components classified especially as an important functional part even among the compressor components.

Tokyu's plastic working technology (aluminum forging and precision technology) is utilized not only perfectioning of the quality that satisfies our customers but also needs of the market in the future like miniaturization and weight reduction.

Tokyu's technology

Car Air Conditioning Parts

The total production volume of aluminum forged parts produced in Japan is about 46,000 tons per year. Among them, our production volume is about 12,000 tons, boasting the top market share in Japan. (2017 results)

As an obligation for using many materials, we challenge ourselves day by day without stopping the process of technological development, such as streamlining production lines and making effective use of aluminum materials to contribute to global environmental conservation by reduction of thorough waste.

Tokyu's technology to support comfortable car life

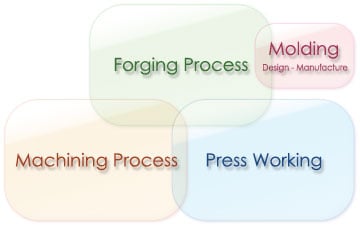

Forging Process

We will propose optimum construction method according to parts shape and materials.

Hot Forging

By heating the material to reduce the deformation resistance, forging a complicated shape becomes possible.

Forgings with a large scale press machine has the techniques that were supported by data inside with the force.

Hot Forging Press Products

We carry out a method of construction and process design according to the shape and size of products.

Hot Forging Lines

(630 ton)

At the headquarter plant (in Oguchi town), we produce products with 12 large scale press machines.

Cold Forging

We leverage advantages of cold forging that can process high precision with fewer resources, and forge difficulty shaping material that was considered challenging to make in the past.

In addition to high-precision processing, our company focuses on a highly efficient product process, and provides process planning that is best-of-breed.

Cold Forging Press Products

In addition to the micron-sized fine forging, we will keep the cutting stock of the after manufacture procedure minimum.

Cold Forging Lines

(630 ton)

We achieve both accuracy and productivity by combining with automatic conveyance.

Cold Forging Lines

(160 ton)

We combine accuracy and productivity by combining with automatic conveyance.

Mold design - Manufacture

It has high reliability to support precision processing technologies and high efficiency production.

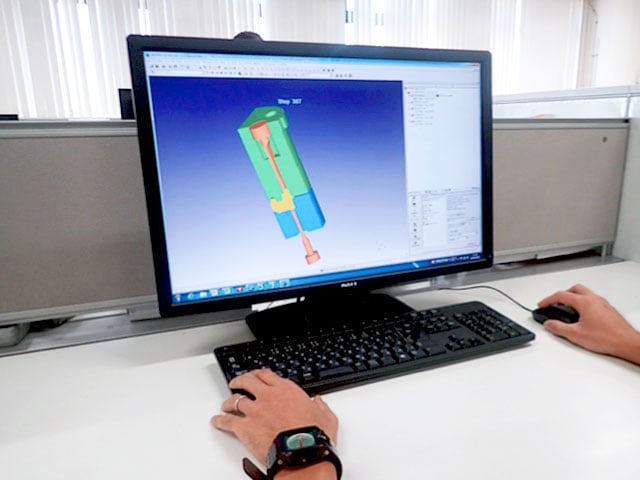

Mold design

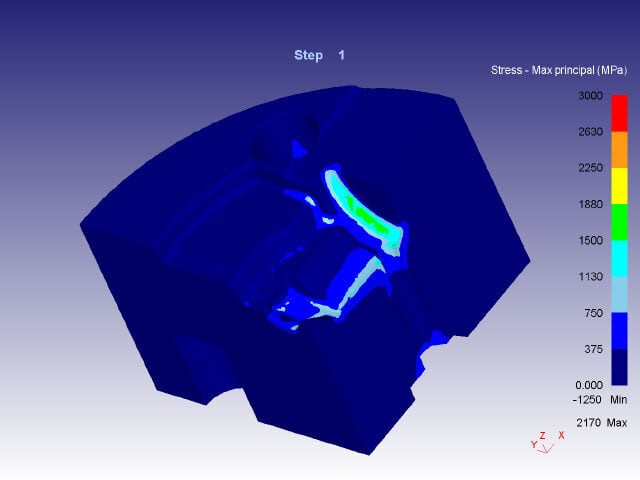

We turn customer supplied blueprints into a 3D model and perform CAE analysis on it to choose the best process and mold structure/material.

By utilizing CAE analysis, we are able to convert traditional "intuition/unwritten knowledge/experience" into data, and constantly accumulate technical skill.

The scene of the work

By utilizing simulation to develop new products and improve existing products, we realize shortened lead time to provide prototypes.

3D Modeling

We propose the best forged shape based on customer's blueprints.

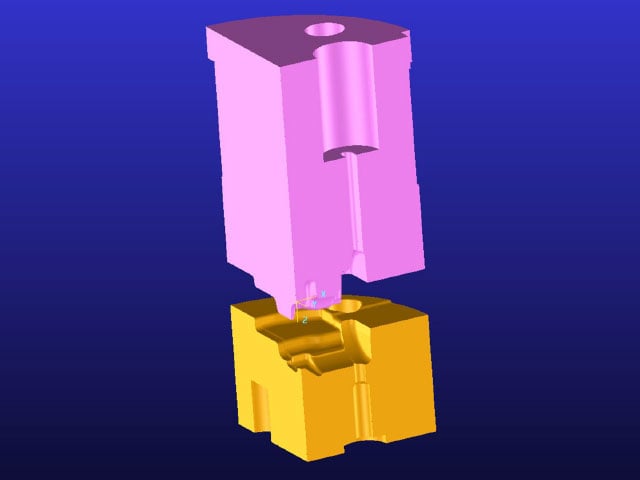

CAE-type stress test

We will design the best mold based on data such as "pressure / heat" obtained from simulation of forging molding.

Mold Making

In keeping with our watchwords "Products cannot be better than the molds used to make them!" we manufacture high-precision metal molds in the environment by controlling temperature carefully, 24 hours (a day). Our molds make a vital contribution to maintaining the quality of our company's products.

Manufacture example of mold

We can process materials that are difficult cutting and ultra precision molds.

Inside the mold production room

We are trying to improve lead time and reduce cost by supplying high precision molds to in-house 24 hours (a day).

Inside the mold production room

Having consciousness not to be satisfied with the existing, we make every effort for the improvement of precision.

Press Working

Car Air Conditioning Parts

Press Working (FBP)

Fine Blanking Process

These products of ours are made by the technology combined with blanking and crushing methods. They have both a smooth punching surface and a fine complex figure.

These technologies satisfy various functions required for valve plate production.

In addition, we can offer products at reasonable prices.

Pressed parts

By complex molding process making full use of the feature of fine blanking, machining-less of cutting is realized.

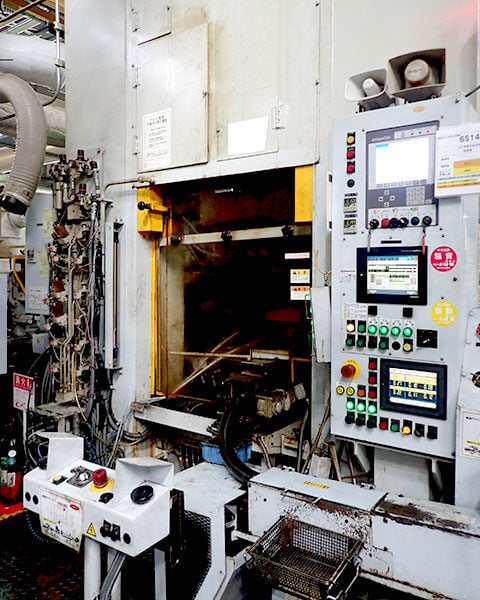

Fine Blanking Press (650ton)

Precision press processing is possible with excellent precision, high rigidity equipments and proper management.

Machining

We will build an optimal line layout to suit many kinds of products.

Line Layout

In recent years, the components comprising automobile air conditioner compressors have become more diverse in order to support the changing market requirements and energy efficiency/miniaturization for environmental considerations. Our company is focusing on the effective use of limited space in order to flexibly support these trends.

In the processing field, production parts exist in both aluminum and iron. Because both types need detailed micron-level processing, we achieve both the process design that is high efficiency as well of high quality and the line layout that maximizes the space.

In addition, by working together with the forging department, it is possible to provide net shape solutions.

Aluminum Forging Parts Processing Lines

(Inuyama Plant)

Aluminum processing line connected in a straight line makes high speed processing, high quality and space saving at the same time.

Iron Swash Plate Processing Lines

(Headquarters Plant)

The headquarters plant is processing cast iron as well as aluminum.

And we are processing the swash plate which is the main part of the variable type compressors.